Cellulose fibers are the most common fiber that we start with as cotton fabric is readily available and affordable. However, cotton does not have the same affinity for natural dyes as protein fibers such as wool, so the cellulose mordant process is different to achieve good results.

The mordant process for cellulose fibers includes pretreating with a tannin, then immersing the tannin treated fabric into an alum solution. This method is one of the earliest mordant methods for cellulose fibers and produces very good results. We use this method regularly as we also love to experiment with different tannins to see how the tannin coloration influences the final color of the textile.

Another mordant method for cellulose is to use aluminum acetate. Aluminum acetate provides bright, clear colors on cotton fabrics if it is used by itself (with no tannin pretreat), but it also requires a post-bath that is referred to as “dunging”.

When we discuss this term, usually a few eyebrows are raised, so let me provide a bit of backstory. Aluminum acetate needs to be “fixed” to cellulose fibers by soaking it in a post-mordant solution. That solution used to be cow dung, or cow patties, as they contained enzymes and minerals (sodium and calcium phosphate) that fixed the alum, removed excess mordant and allowed for better color penetration on the fibers. How this discovery was made is unknown to me, but there are a number of processing methods from ancient cultures that use dung as an ingredient, most likely for their mineral and enzyme content. For example, some leather is tanned in dung to soften the hides.

Fortunately for us, we don’t need to wander through a cowfield to find the ingredients to fix our aluminum acetate mordant. We can use calcium carbonate (chalk) in the dunging process. If we are printing with thickened mordants, then a combination of calcium carbonate and wheat bran will help remove the paste residue and fix the mordant to the textile.

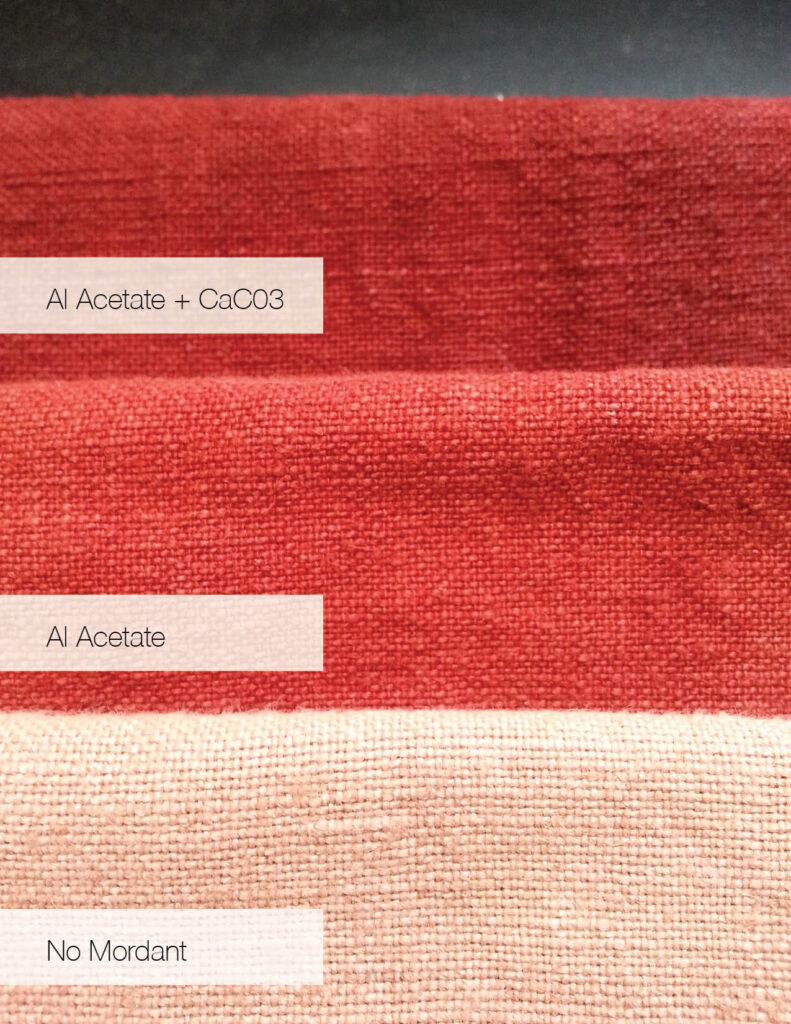

If you are wondering if all this is really worth it, the answer is yes. Check out the comparison that we did where we dyed three pieces of fabric with different mordant processes, all in the same madder dye bath. The top sample is aluminum acetate with a chalk (dunging) post bath. The middle sample is aluminum acetate all by itself. The bottom sample is an unmordanted piece of fabric that we threw in out of curiosity. Notice how the madder has hardly any affinity at all to the unmordanted cellulose fabric and only very lightly tints the fibers.

We often say that mordanting is one of the most important steps in natural dyeing, and our little experiment shows that the extra step of using chalk as a post bath is key in getting great color on cotton. Instructions on how to mordant with aluminum acetate and chalk are here.

FAQ

- Can you pretreat aluminum acetate with a tannin and do you still need to do the dunging step?

- Answer: we don’t often use tannin + aluminum acetate, but I have heard that other dyers use tannin and liked their results. I would still use the calcium post bath.

- Please provide more information about using wheat bran to remove print paste

- Check out this tutorial with Arielle Toelke on how to use print paste thickener and the dunging process to remove excess paste.

Using calcium and wheat bran to remove excess alum and paste. Image courtesy of Arielle Toelke

References

The Art and Craft of Natural Dyeing: Traditional Recipes for Modern Use by J.N. Liles. His discussion of dunging is called “fixing solution” and he even provides the amount of cow or sheep dung needed, should you want to get really authentic. Otherwise, use calcium carbonate,

The Art and Science of Natural Dyeing: Principles, Experiments, and Results by Joy Boutrup and Catharine Ellis. They discuss dunging for aluminum acetate mordanted fibers and provide a dunging solution for removing excess thickened mordants.