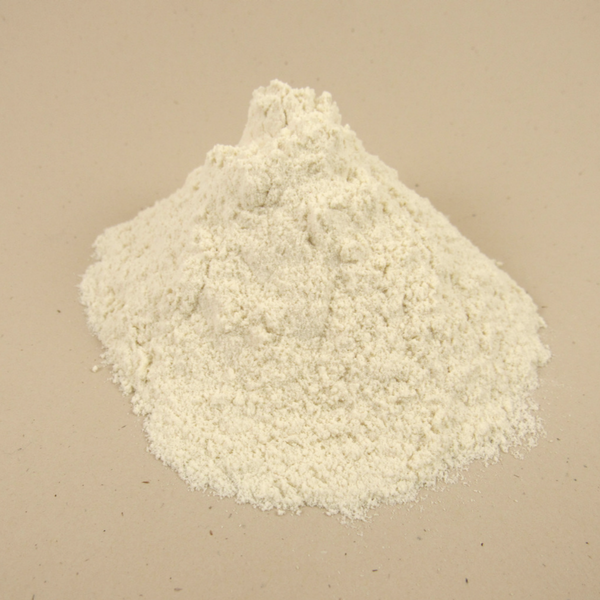

Print Paste Thickener

$16.00 – $75.00

In stock

Description

We use organic print paste thickener (replaces Gum Tragacanth*) as a thickener to paint or print with natural dyes on fabric. In addition, it is an organically certified water-soluble carbohydrate gum mixture. Similarly, it performs very well in thickening dyes and pigments for printing and painting.

Print paste thickener will dissolve readily in cold or hot water. After that, it forms a smooth translucent paste to mix with powders or liquids. 250 grams of Organic Print Paste Thickener will make approximately 8 liters (two gallons) of thickened paste for painting or printing with natural dyes.

*Gum Tragacanth is currently in limited availability. Most of the world’s supply comes from Iran which is now a restricted trading partner to the US.

From our Feedback Friday series:

I have a question about the print paste thickener – I want to use natural dyes/pigments for screen printing onto textiles, but want the binder to be either organic or at least a natural base, not synthetic like the one we have in the print room here. I’m trying to gather some info on what the best base to use would be.

Is the paste thickener just gum arabic, or is it something else? Have you tested this before and seen if it fixes onto the fabric well? I don’t know if you could direct me to someone you know who has use natural dyes & pigments on textiles this way, or if you could offer any advice? Or know of any UK stockists that have as great a selection as you do.

There are two steps to using natural dyes as thickened pastes for printing. The first is the thickener which may be our print paste thickener, guar, gum tragacanth or a mixture of other plant gums. We do not use sodium alginate because it seems to cause unwanted color shifts in the paste. Natural dye pastes are usually translucent. If you want an opaque effect, the thickener should be an opaque medium, but it can also make the natural dye color paler.

The binder may be either a mordant (mordant the fabric first, then dry it until it’s almost dry) or a physical binder. You can use any non-toxic conventional binder, but be aware that some of them may alter natural dye colors. Or, you can experiment with fresh made soy milk, casein or other natural binders. Alum or iron-based mordants are the only ones that will have washfastness properties, as they provide the chemical bond between fiber and natural dye. Soy milk is a “glue,” and water soluble, so will eventually lose its hold on the paste. Some printers mordant, print, wash/dry, and then coat with soy milk as an additional binder.

Additional information

| Weight | N/A |

|---|---|

| Dimensions | N/A |

| Weight | 100 gm, 250 gm, 500 gm |

Related products

-

Cellulose Scour

$7.00 – $16.00 Select options This product has multiple variants. The options may be chosen on the product page -

Soda Ash

$6.25 – $19.00 Select options This product has multiple variants. The options may be chosen on the product page -

Organic Soybeans

$7.00 – $13.50 Select options This product has multiple variants. The options may be chosen on the product page

You may also like…

-

Cream of Tartar

$18.00 – $60.00 Select options This product has multiple variants. The options may be chosen on the product page -

Tara Powder

$26.00 – $50.00 Select options This product has multiple variants. The options may be chosen on the product page -

Wheat Bran Mordant Assist

$5.00 – $10.00 Select options This product has multiple variants. The options may be chosen on the product page