Every week, we are emailed with questions from our natural dye community asking simple and complex questions that we thought might be worth sharing. Of course, all of your burning questions are answered by natural dyer in chief, Kathy Hattori, Founder of Botanical Colors.

I’m about to place an order but I can’t make up my mind on what to choose between gallo-tannin and Tara.

In the gallo description it says that “Tara is a very light tannin, similar to our tannin extract.” It also says that gallo “contains approximately 50-60% tannin” and Tara is “between 30 and 50% tannin”. If I understand correctly, gallo can be the same or twice the strength of tara?

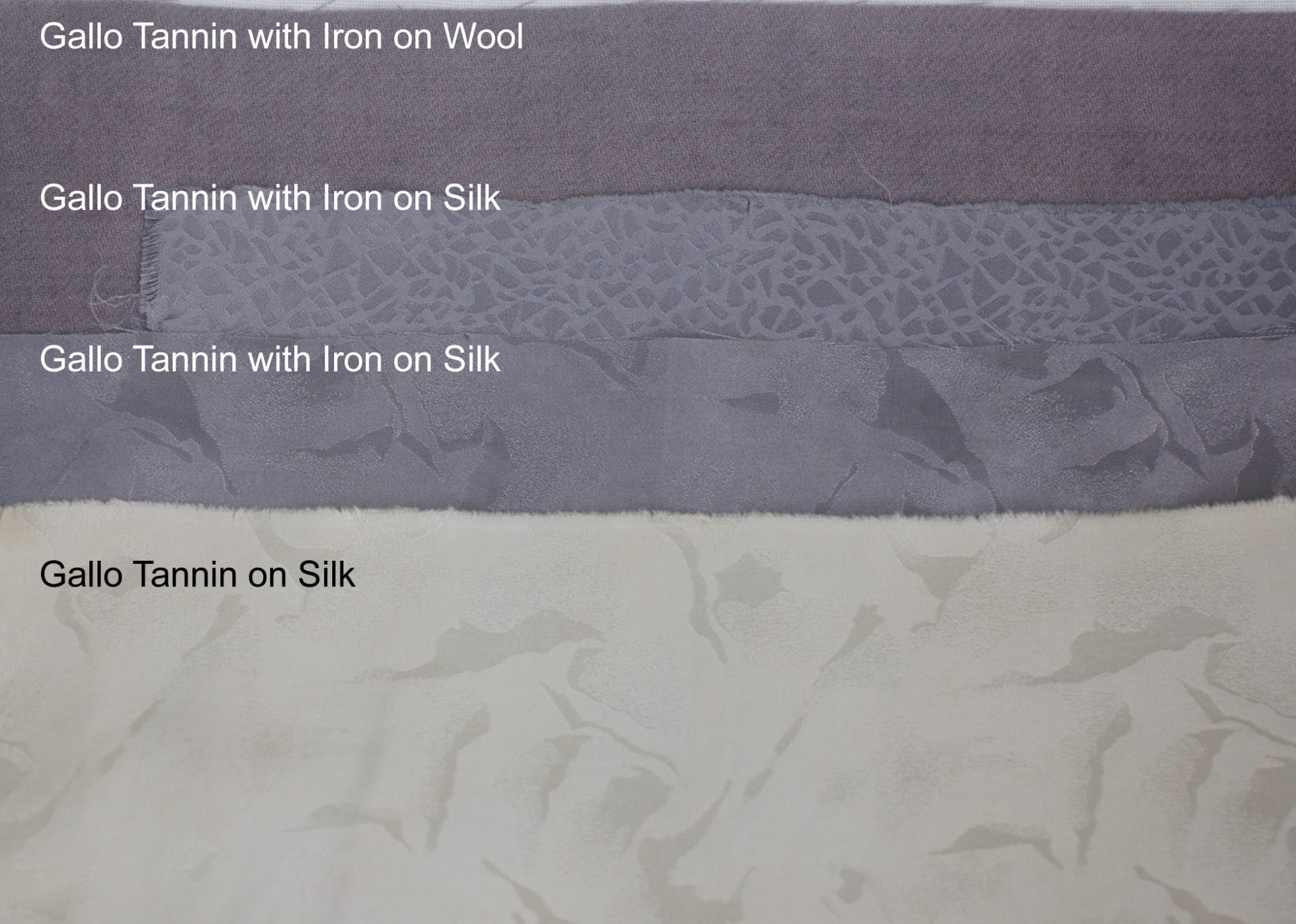

It is possible that gallo-tannin has more tannin than tara but the percentage varies, but generally, gallo-tannin is the “strongest” tannin.

I’m developing a line of natural dyed table linens. Up to now, I was using aluminum acetate + gallo or tara pre-treatment + wheat bran post-bath method for mordanting cellulose fabrics.

The best procedure for color and lightfastness is tannin first, then aluminum acetate, then wheat or calcium carbonate post bath.

I know that a tannin pre-treatment has an impact on the final color, my question is would using a colored tannin for pre-treatment help make the gradual fading of color less visible?

Again, possible. The way I look at it is that the light tannins influence the color, so I normally go toward light tannins, not wanting to influence the shade. However you are asking if a darker tannin will influence a darker shade, so I have to say that it is probably the case. Great question!

Will using a higher WOF aluminum acetate increase the colorfastness OR the “darkness” of the shade? Same question for tannins, will a higher WOF increase colorfastness OR “darkness”?

It is possible to use up to 10% aluminum acetate but then costs go up. What I am seeing with most cellulose fibers is that they require a very thorough scour in 160-180F water for 20-30 minutes with up to 4% soda ash. We normally use 1% for PFD fabric, 1-2% for lightweight fabrics and 2-4% for heavy fabrics. The scour water looks like black tea, and this can impede mordant and color take-up. Rinse well then proceed to tannin bath.

1. Super thorough scour as above, then tannin, process hot (160F) for 1 hour. Rinse and remove. You can let it soak overnight in the bath too after bringing it to temp.

2. Aluminum acetate at 8%, process overnight cold by soaking in solution. I don’t rinse after this step.

3. Wheat or chalk post-bath, 15-30 minutes, cold.