Kathy is currently creating magic at Sanborn Mills for her Nerd’s Guide to Mordants workshop. We decided to give you a little taste into all of the beautiful mordant variations she is creating for this workshop and some of the key considerations you should take into account when beginning to mordant. For all of you budding mordant nerds out there, here are some highlights of what is covered during the class. We are working on bringing this class to you in online form, so here is a little teaser while you wait!

What is a Mordant?

A mordant is a typically a mineral salt that fixes with the fiber allowing natural dyes to bond to it. Mordanting is the most important process of preparing fibers to accept color. For us it is the most important step to improve light and wash fastness, and using a mordant helps to ensure the most durable and long-lasting colors. With the exception of indigo (as a vat dye, it does not require a mordant), this is not an optional step. However, there are many different mordants you can use. Deciding which mordant to use comes down to the types of fibers you want to dye and how much time or energy you wish to spend. The table below explains the different mordants that we offer and the characteristics of each one. The mordants we offer are generally accepted as non-toxic, and we encourage you to work in a well-ventilated area and to use gloves, dust mask and eye protection when weighing powders. Always supervise children when working with natural dyes, and keep all ingredients away from children and pets.

Mordant Decision Making

There are many mordants, and choosing which one can seem a little overwhelming, but if you can categorize fibers in two general categories, the mordant options become clearer. Different mordants can perform better on different kinds of fibers. We divide fibers into two categories.

The first category is cellulose fibers, also called plant fibers. This category includes all plant-based fibers, such as cotton, linen, hemp, viscose, lyocell, bamboo and other similar fibers.

The second category is protein or animal fibers. This category encompasses any fiber that comes from an animal, including wool, cashmere, alpaca, mohair and silk.

If you are dyeing a blend of protein and cellulose fibers (such as wool/hemp, silk//bamboo, or silk/cotton), use mordants that can dye both types, as seen below. Another option is to mordant for one of the blend ingredients and be aware that the other blend ingredient may take the dye a little differently.

As a general rule, synthetic fibers such as polyester and acrylic will not dye well with natural dyes.

For Cellulose or Plant Fibers

We recommend aluminum acetate or the tannin-alum-chalk method if you are dyeing cellulose fibers. Both of these are multi-step mordants, but we’ve found they deliver excellent results.

For Protein or Animal Fibers

We recommend aluminum potassium sulfate, aluminum sulfate and aluminum triformate for protein fibers. These three mordants are easy to use and deliver excellent results.

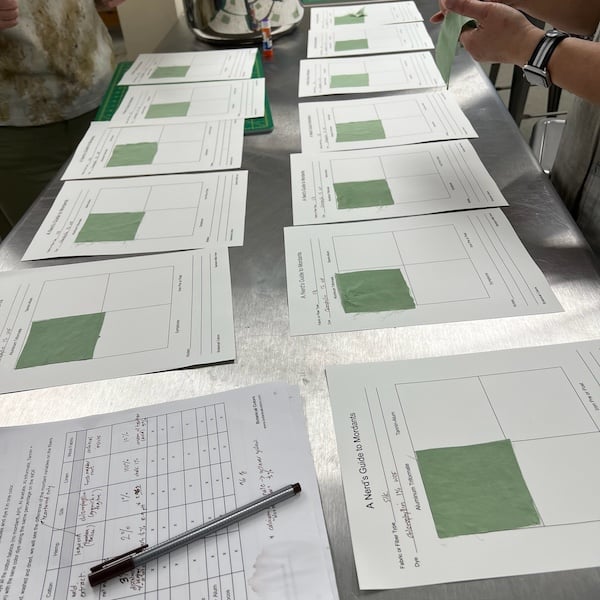

For basic mordanting, refer to this table. In this workshop, this is what we will be discovering. We are mordanting each fiber with each different mordant, then cutting swatches and comparing results.

| Mordant | Fiber types | Features | Percentage to use |

| Aluminum Acetate + calcium carbonate after bath | Cellulose fibers | Produces bright colors. Does not require heat | 8% Al Acetate and 2% Calcium Carbonate post-bath |

| Aluminum Potassium Sulfate | Protein fibers | Easy to use. Produces bright, clear colors | 10% Aluminum Potassium Sulfate |

| Aluminum Triformate | Cellulose and protein fibers | Easy to use. Does not require heat/energy | Use bucket method at 20g/L |

| Symplocos | Cellulose and protein fibers | Bio-based from dried leaves rather than mineral-based | Use Turkey Red Oil and symplocos at 50% WOF (note: this is a new procedure and will be a total surprise!) |

| Tannin and Aluminum Potassium Sulfate | Cellulose fibers | Most lightfast mordant for cellulose fibers | Use tannin bath at 10%Use Aluminum Potassium Sulfate at 15%Use Soda Ash at 1.5% WOF |

| Iron | All fibers | Adds a darker or gray tone to colors | Use at 1% WOF |

We also have a very robust HOW TO section on mordanting and other recipes! Please have a look through and bookmark them for your reference!