This week: Brittle fabrics from mordanting and scouring and a how-to on thickening dye extracts to print

Every week, we are emailed with questions from our natural dye community asking simple and complex questions that we thought might be worth sharing. Of course, all of your burning questions are answered by natural dyer in chief, Kathy Hattori, Founder of Botanical Colors.

I have been noticing on my scoured habotai silk develops yellow lines and marks if stored over days. The fiber turns brittle where the lines/marks appear. I see these lines on mordanted silk as well, so thought it may be something is not right with the way I was scouring (I use Genteel mild detergent and maintain the temperature at 80 for an hour). I have read in many places to use Orvus paste for scouring. Is there an alternative to Orvus. What am I doing wrong?

If you are using habotai (China silk) and it is pure white, there is probably not a great need to scour the fibers as commercial habotai is a fairly clean fiber. It sounds like the scouring and mordanting process you are using is creating lines and marks. If the detergent you are using is making the fiber brittle, then the product is too harsh. You can try a mild dish soap (like Dawn, the one they use to clean birds during oil spills) and use a small amount, then immerse the fabric in this solution, bring to 60C, and hold for 15-20 minutes. It’s also possible that you are heating the fibers too long as well.

Orvus Paste was developed to wash livestock (sheep and cows), so it is industrial grade shampoo. It has many of the same ingredients as Dawn dish soap.

What amount of natural dye powdered concentrates should one use with your printing paste? I couldn’t find approximate proportions. Does one just need to experiment? I understand there is some variation from light to dark colors but a starting point would be helpful given the product is a little on the pricey side. Pricey, totally worth it, but I would like to avoid wasting product, if possible. I saw the part about dissolving the dye in water first but no amounts. Thanks.

It depends on the dye because they all have different tinctorial strengths, but the rule of thumb is to start with about 1/4 teaspoon print paste thickener for the super strong dyes (logwood, cochineal extract, weld, madder extract) and 1/2 to 1 teaspoon for the dyes with a lower tinctorial strength. Use about 1-2 ounces of super hot water, stir well. That way you can get a concentrate as the print paste dilutes the shades. If you have leftover paste/ink, it can be refrigerated for about 5 days. Once it starts growing mold, it is no longer very effective.

Related products:

Botanical Inks: Plant-to-Print Dyes, Techniques and Projects by Babs Behan

The Art and Science of Natural Dyes: Principles, Experiments, and Results

Make Ink: A Forager’s Guide to Natural Inkmaking

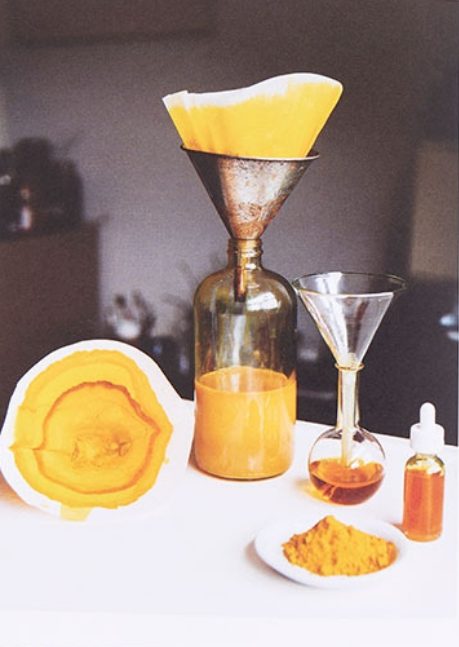

(Top image: From Jason Logan’s book Make Ink: A Forager’s Guide to Natural Inkmaking)