Mordanting and scouring should be at the top of your things-to-do list before natural dyeing. Botanical Colors Founder Kathy Hattori recently took on as many questions as was humanly possible to clarify the processes.

Before reading, also please see our How-To Scour and How-To Mordant pages.

Scouring Questions

If I use untreated and unbleached fabric, is it a must to scour the fabric or is washing it enough?

If you mean by “untreated” that it has never been scoured, then you should scour. If untreated and unbleached means it is also prepared for dyeing (PFD or RFD), then you can wash the fabric first.

I’ve seen some instructions for scouring cellulose fiber that say to just use soda ash. So I’m wondering what the Cellulose Scour adds to the process?

Cellulose scour is a surfactant and helps with the scour process but it is optional. If you have only Soda Ash, it’s perfectly fine to use it alone.

What is a good scour for repurposed garments?

Soda ash at 1% is usually good for any cellulose fabrics. Silks need to be treated more differently. If the garment is natural colored (not dyed), a gentle wash in the washing machine is probably enough. Dyed silks often bleed like crazy, so check to see how stable it is. If it is not stable, then I would not attempt to scour and overdye it.

Mordanting Questions

Can you use the same mordant bath several times?

Yes. See this link on how to recharge a mordant bath.

Can you prep several materials in same mordant bath, dye one at a time, letting others dry and dye at a later date?

Yes. Check out this link – as long as everything is using the same mordant (like aluminum sulfate), then you can use some immediately, keep some damp for near term use and dry some for future use.

What is the best pH neutral soap to use when washing fabrics after the mordanting (and dyeing

process)?

We like to use Seventh Generation laundry soap, or any laundry soap without dyes or fragrances.

I read that the soy process is more of a modifier than a mordant, what do you think?

I use soy-milk to mordant fabric. Is this equal to alum or any other mordant, or isn’t this a mordant?

Soy is considered a binder, not a mordant. Its primary function is to “glue” the dye to the surface of the fabric and it may have some affinity to natural dyes due to its high protein content. It is not considered durable compared to alum mordants as it does not chemically bond with the fiber but sits on the surface and holds the dye to the fabric, so it’s more susceptible to washing and rub-off.

Do you always mordant, even if you’re using a tannin-rich dye bath?

Almost always, but not always. Many black recipes do not require alum mordanting.

Which type of mordanting do you think ensures color fastness?

Color fastness is a function of the dyestuff and the mordant, not the mordant alone. If you dye a mordanted fabric with a fugitive color, you will still have problems with colorfastness. Mordanting with alum is considered a good choice for ensuring colorfast results.

Is it common to use alum with cream of tartar?

Alum with cream of tartar is mostly used with animal protein fibers such as wool and helps maintain softness and brightens colors, shifting them more yellow rather than blue. A good example of this is how it works with cochineal. For plant fibers, cream of tartar can help shift the pH of a dye bath, but it is not normally used with mordanting.

Or to use alum with soda ash? Or is it also okay to use only alum?

It is totally okay to use only alum with animal or protein fibers. Alum with soda ash is used as an alternate mordant for cellulose or plant fibers. It works best if you use a tannin bath prior to the alum bath.

Is there any preferred mordant to use on silk and cotton?

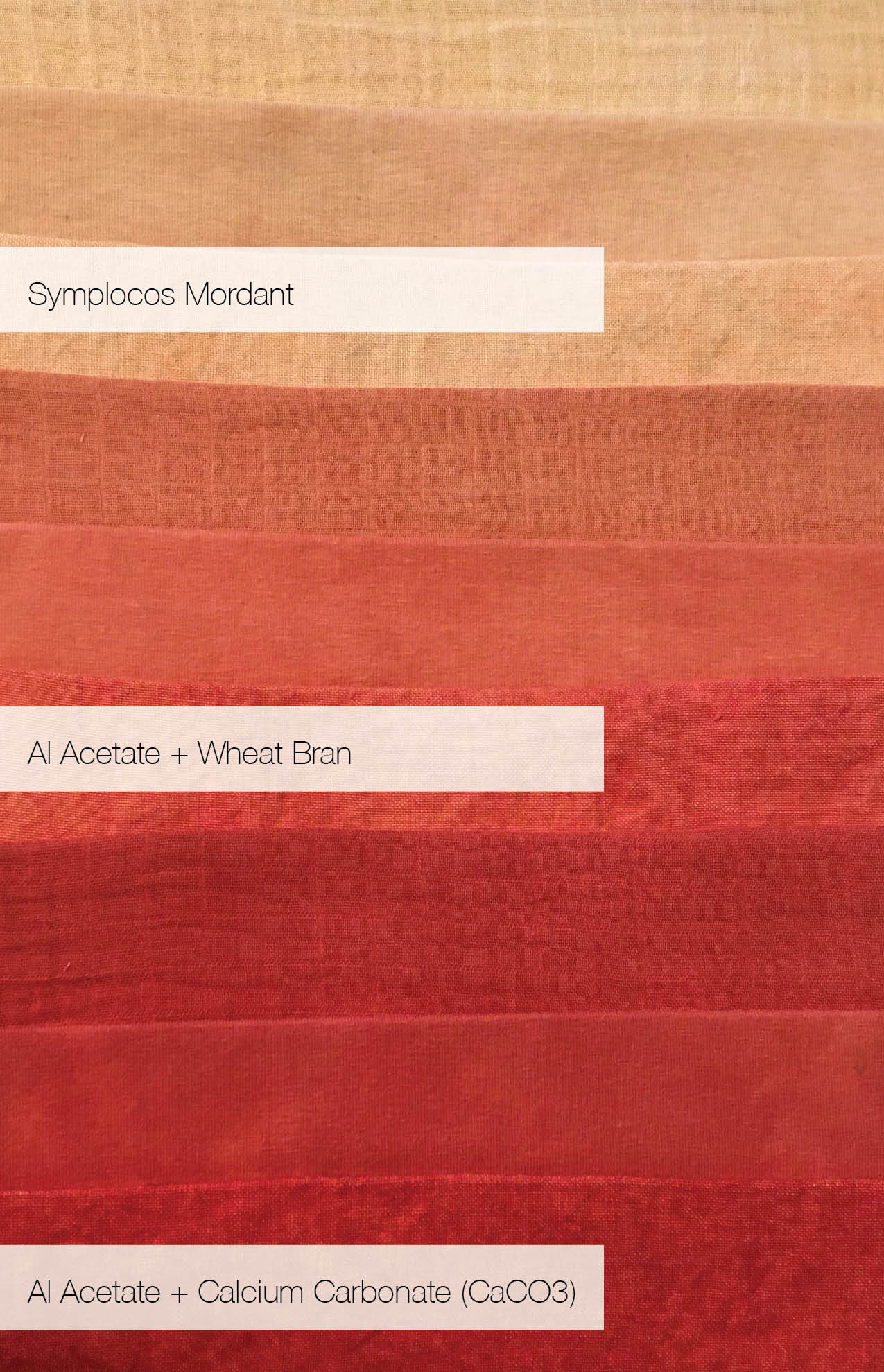

It is possible to use tannin and aluminum sulfate or aluminum acetate and wheat bran post bath.

When is it important to use a tannin as part of the mordant process on cellulose fibers?

Tannins will help with lightfastness. The procedure is to immerse the textile in tannin first, then in alum. Be aware that tannins have their own unique color, so the fabrics will take on the shade of the tannin.

Can you please go over the ideal temperature ranges for scouring and mordanting of various fiber types? I feel like I see conflicting information about which fiber is best mordanted at lower or higher temperatures.

Plant fibers: Mordant at 110 F or lower (hot tap water or even lukewarm). Aluminum acetate will form particles if it is heated above 140F.

Silk: Kathy says “I have always mordanted silk hot (160F), but The Art and Science of Natural Dyes says that heat mordanting can be damaging, so I now mordant cold using cold water from the tap.”

Wool is typically mordanted hot (180F) in order to have the mordant quickly penetrate the scales of the wool fiber. It is possible, however, to mordant cold and mordant longer. For example, a hot mordant may take about 45 minutes, but a cold mordant will take 2 days or longer. We will often mordant wool by starting with hot tap water and aluminum sulfate, and then let the entire mordanting bucket cool. Then we hold it in the mordant solution for 2 days and start dyeing then.

We are now carrying a cold water mordant for wool called Aluminum Triformate. It is easy to use because you create a container of dye and then add wool yarn or fabric to it and let the fibers soak. There is no need for heat, but overnight soaking gives deeper colors, and rinsing the fibers before dyeing creates a beautiful rich color. We have complete instructions here and I also presented the mordant and my experiments on Feedback Friday.

I want to use tannin and alum sulfate on cellulose, will I still get good color?

You’ll get beautiful color. Be aware that the color of the tannin will influence the dye color, so choose a light tannin such as Gallo Tannin or Tara Powder for a light tannin. If you love to experiment, you can create a range of amazing shades by using the yellow or darker tannins, too.

If I am using the “tannin/alum” mordant method, when would I use chalk? Is there a benefit to ending in a tannin bath?

Some dyers felt like they got better and deeper shades by repeating the tannin/alum steps twice. I never have done this. If you want to use a chalk bath, it would occur at the end of the mordanting process.

Can you talk about the safety measures needed when using iron?

Check out our iron instructions. We review safety issues in detail.

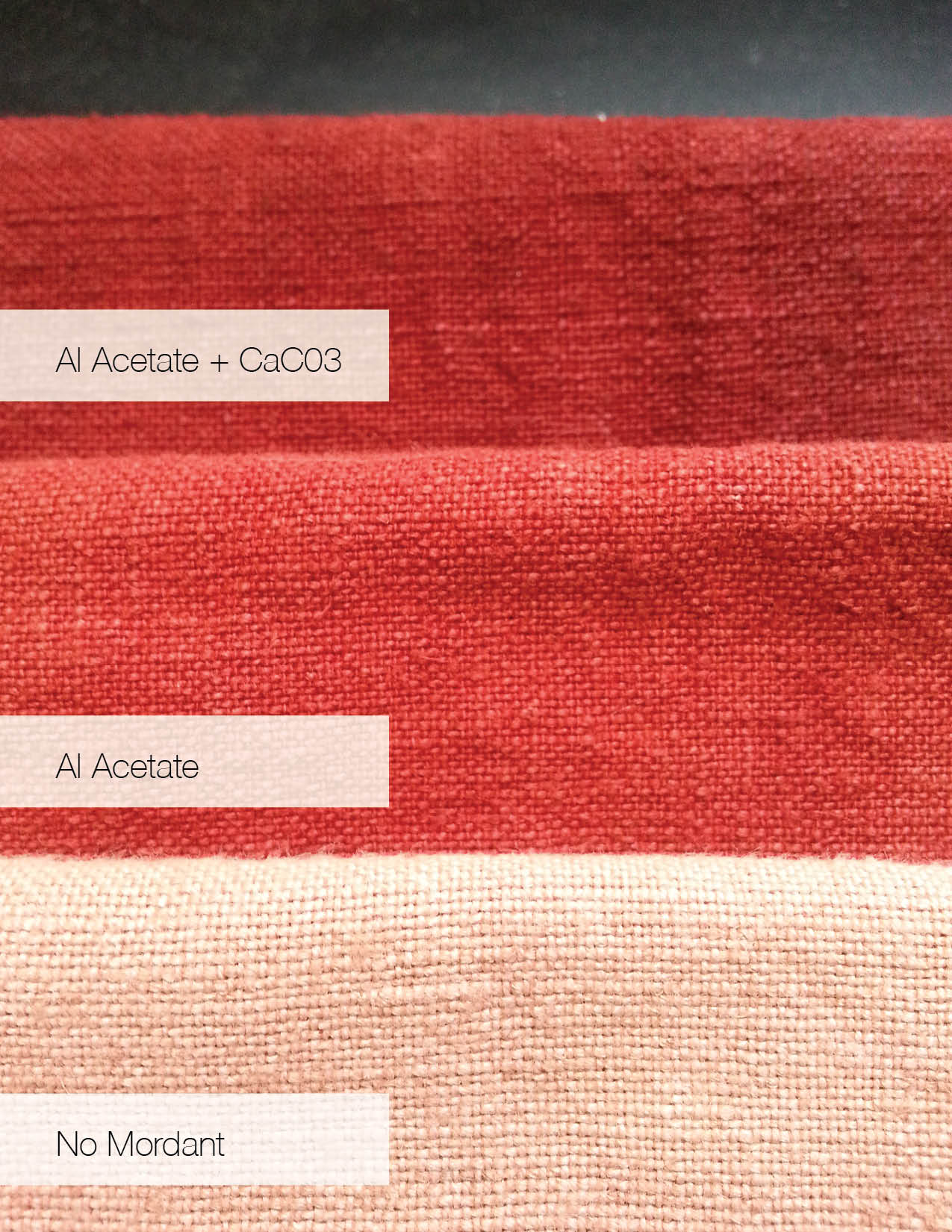

Is there any advantage to double mordanting with alum? E.g. to complete the process twice

It does have some benefit but we use a hefty amount of alum in the beginning (like 10-20% wof), so I’m not clear if there’s additional benefit by double mordanting. It might be better to “cure” or age your mordanted fibers in the mordant bath for 3-5 days. We did an experiment and fabrics mordanted and cured dyed more deeply than freshly mordanted goods.

Whats the deal with using an aluminum pot as a mordant?

Some dyers feel that it’s a substitute as an alum mordant. I have not tried this method. I can’t imagine that an aluminum cooking pot would shed enough alum to be useful as a mordant, but it might modify the dye color a bit.

Any recommendations about how to scour wool top? It’s fragile.

You should not have to scour wool top as it is already highly processed and clean in order to go through the top-making machinery. If you want to mordant it, try enclosing it in a mesh bag.

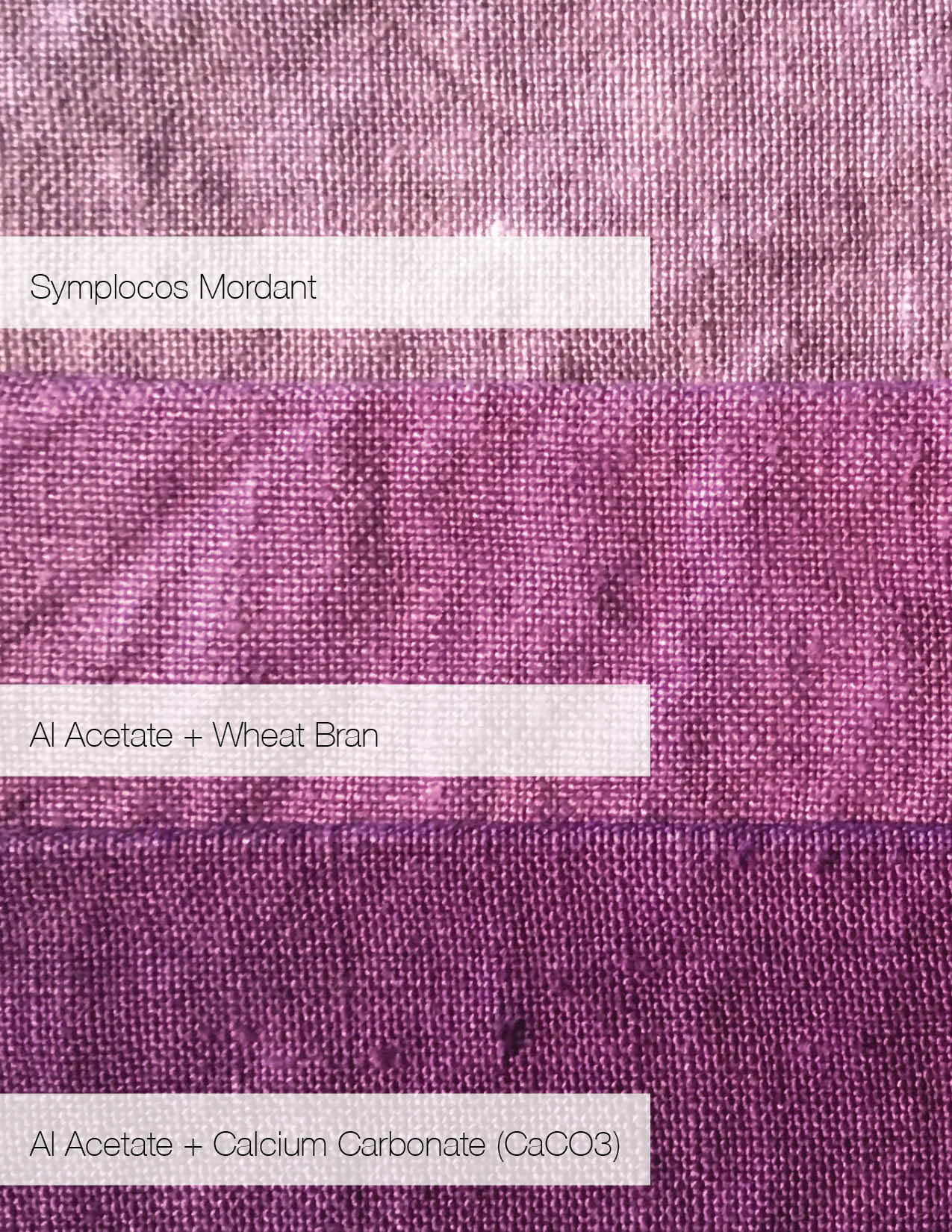

What are your top mordants to use for cellulose fibers?

aluminum acetate and calcium carbonate

aluminum acetate and wheat bran

tannin and aluminum sulfate

Do you mordant and then post mordant with calcium carbonate prior to dyeing?

Yes.

With tannin, can you dry fully before mordant bath? and, if so/if not, why?

I think it’s possible dry before the mordant bath, but really the most logical stopping place is to dry after the mordant step, and save the calcium carb or wheat bran for later. The tannin is not strongly attached to the fiber but adding alum bonds it into place.

I dye with indigo. I bought some dyed wool to dye with indigo to change the color. I did not mordant it as it had already been dyed, but the indigo is coming off in my hands no matter how often I have rinsed and washed the wool. What can I do to have the indigo adhere to the wood?

I’m afraid I can’t offer much help with this – if you are using a 1-2-3 vat, it could be any number of things, or that the original wool was not properly scoured. Sometimes if I have a color that is crocking like crazy, I will dry the fiber bone dry, let it sit for about 3 weeks, and then try washing again. That can help.

How do you work with measurements in percentages (without scale)? Measurements are so difficult for me in dyeing

If you don’t have a scale, the only thing you can do is calculate the percentage needed in grams, then go online and convert to volumetric measurements (look for grams to teaspoon calculators. A lot of cooking sites have this type of information). It will never be exact, but if you use them consistently, you will get consistent results.

When you refer to alum, do you mean aluminum acetate or aluminum sulfate?

The common term for “alum” means aluminum sulfate.

What plant tannins do you like to use with cotton? Like oak gulls? Walnut?

Oak galls, myrobalan, tara powder, pomegranate, quebracho moreno, walnut and cutch all are good tannins.

Aluminum acetate/cellulose fibers

My aluminum acetate often does not completely dissolve even with boiling water. Do you recommend putting the undissolved aluminum acetate in the vat with the fabric/textiles or would you strain? My assumption is that by excluding the undissolved alum acetate, one is reducing the amount used for the WOF.

Aluminum acetate is tricky to dissolve, but it should eventually dissolve. Sometimes I leave it overnight and it dissolves completely. I do not recommend putting lumps of undissolved aluminum acetate in the mordant bath. If you can’t wait, then strain it. If it is a small amount of aluminum acetate you are straining out, it should not dramatically change your end results. If you have a lot of aluminum acetate that is undissolved, try a larger container.

I have some cotton and linen t-shirts that have faded over years of wearing and washing. Do I need to re-mordant before over-dyeing them? Especially if I usually wash them with regular laundry detergent with the rest of my clothes, should I also scour them again?

If you mordanted years ago, a second mordant bath shouldn’t hurt. If they don’t have fabric softener on them from laundering or drying, then you should not need to re-scour.

I recently mordanted some cotton in an alum acetate bath and then did half in a chalk after bath. The swatch from the chalk after-bath didn’t seem to make a big difference, do you still recommend to do this? And if so how long do you recommend leaving the fiber in the chalk after bath for?

Check our our instructions on How to Mordant. Although you may not see a difference, chemically, the post-bath helps the aluminum acetate work better and give clearer colors.

Aluminum Sulfate/ Animal Fibers

What is your favorite/preferred mordanting process for plant-based and animal-based fabrics?

Check out our mordanting instructions. I am partial to aluminum sulfate with or without Cream of Tartar for wool and animal fibers, aluminum sulfate for silk, and aluminum acetate for plant-based fabrics.

When I use a plant dye on my all natural wool yarn, I frequently end up with a duller looking yarn than I started with. The color looks flat and the slight sheen that the yarn had previously, is gone. Could it be my mordant? I use 12% Alum and 6% cream of tartar based on the wof.

It’s possible that you are using a bit too much alum for your water. Sometimes excessive alum will make the fibers a little rougher, or tacky when using hard water. As well, the yarn appears slightly “cottony.” Try using about 8% alum and 5% cream of tartar and see if the yarn quality improves.

How can I keep my wool yarn from blooming when I am scouring or mordanting? I have been careful about temperatures.

I think once water penetrates the fibers, it’s impossible to stop the fibers from relaxing and puffing up a bit. Is there a reason why you want to prevent this?

Calcium carbonate/wheat bran

After removing fibers from a calcium carbonate bath, the direction is to rinse lightly. Should one feel the chalk on the fiber or not?

If you feel chalk on your fibers, then rinse more.

If one is mordanting to dye in the future, should one rinse completely post wheat and/or chalk bath, prior to drying and storage?

Yes, definitely rinse away any wheat bran flakes or excess chalk.

What is the best way to dispose of a calcium carbonate bath?

Add a capful of white vinegar to neutralize it and dispose down the drain. Calcium carbonate can also go into a garden as a soil amendment.

Resources for fiber

Do you have a good source for quality remnant cloth: silk, 100% cotton, wool, etc to use as swatches for testing? Also, sources for loose wool?

If you are looking for used fabrics for swatching, you might want to check out thrift stores and make sure you check the label for the fiber content. If you are looking for local wool, yarns or other products, check out the Fibershed Affiliate directory in your area. They will have links to ranchers and farmers in your area.